Safety & Warning Tags

LEM manufacturers a complete line of safety tags and warning tags, in the form of plastic safety tags, self-laminating safety tags, and durable safety tags that meet all applicable OSHA (Occupational Safety & Health Administration) and ANSI (American National Standards Institute) standards. These safety tags draw attention to potentially dangerous or abnormal situations in your plant, such as High Voltage or Confined Space. Safety tags with highly visible printed headers (DANGER – CAUTION – NOTICE) are effective both indoors and outdoors. These safety tags provide the necessary accident prevention information on a durable safety / warning tag.

Safety Tags, Warning Tags, Danger Tags

Power generation facilities contain a vast amount of machinery and equipment requiring monitoring and routine maintenance. Safety precautions and procedures are critical in these facilities to alert the workforce about unusual conditions, special operating instructions, and information on the condition of lines and equipment. Safety Tags, which include Danger tags, Warning tags, Accident Prevention tags, Scaffold tags, and Equipment tags, are an important tool to provide effective warnings of potential dangers and hazards. All of LEM’s Safety Tag products meet applicable OSHA (Occupational Safety & Health Administration) and ANSI (American National Standards Institute) standards. These tags alert to potentially dangerous or abnormal situations such as High Voltage or Confined Space by means of clearly visible printed headers denoting DANGER, WARNING, CAUTION and NOTICE. LEM vinyl safety and warning tags withstand moisture, dirt and grease and can be written on with pencil, ballpoint pen, or permanent marker.

LEM's Safety Tags are available with many options:

Self-sealing polyester covers: These covers will permanently protect information and allow you to apply photos and personalized specific information for lock-out tag-out, compliance, accident prevention, regulatory compliance, and safety. These covers make the tags weather-resistant, water-proof, and tamper-proof.

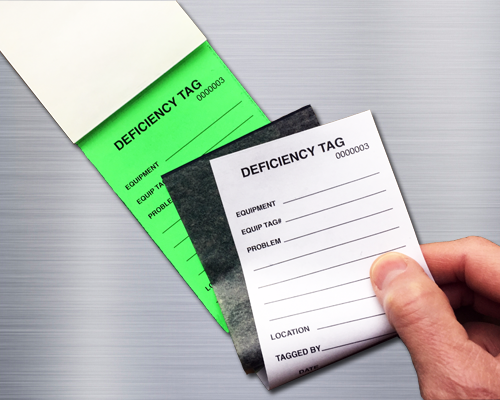

Carbon set tags: These tags provide instant on-the-spot copies for record keeping of field information during inspections. Once the carbon copy is removed, the tag can be sealed with the self-laminating polyester cover and the information becomes permanent.

Grommets: Safety tags have either a metal grommet or a plastic, non-conductive and non-corrosive grommet. Both styles provide a secure attachment point withstanding 50 – 80 lbs. of pull force. This durable construction will prevent unauthorized removal of the tags to maintain a permanent display of critical safety and regulatory information.

Carbon Set Tags

LEM Safety Tags with carbon sets make inspection easier to correct deficiencies at hand, as well as provide carbon sets for simple record keeping. These industrial safety tags are made to meet your specific design and contain your defined information. These regulatory compliance tags are durable tags that are available for Chemical Safety, Industrial, Accident Prevention, Lock-Out Tag-Out, and all tags requiring DANGER, CAUTION and NOTICE headers. Once this durable safety tag is self-laminated, the information is tamper-proof and permanent. Simply remove the carbon sets prior to self-laminating the safety tag. Use these safety tags to mark bottles, drums, or containers with hazard information.

A carbon set safety tag is the ideal non-compliance tag and inspection tag. This safety tag provides carbon copies for easy record keeping. Write-on safety tags, warning tags, and other specialty safety tags (such as vehicle hang tags) are available in Tyvek™ and write-on vinyl. These safety tags will accept marker pens, ballpoint pen, and pencil. The write-on surface is durable and moisture proof. This write-on vinyl tag may be re-used when a grease pencil is used to apply the information.

Tags available in this format:

PCB, NFPA, OSHA and ANSI

Self-Laminating Tags

Danger Tags, Caution Tags and Notice Self-laminating Tags provide a self-sealing polyester cover that will permanently protect information and allow you to apply photos and other exact information for lock-out tag-out, compliance, accident prevention, regulatory compliance and safety. Once this durable industrial danger tag is self-laminated, the information is tamper-proof and permanent. Use these danger tags to mark for Confined Space, Danger, Caution, Compliance, accident prevention, lock-out tag-out, and to mark bottles, drums or containers with hazard information.

Scaffold Tags

Scaffold tags function like a combination of an accident prevention tag and an inspection tag. They warn of the status of erected scaffolding: whether it is in the process of being erected or dismantled, and if it complies with building codes. It also advises workers whether or not the scaffold is safe to climb.

LEM’s scaffold tags are self-laminating, which allows the opportunity to add variable information to the pre-printed tag, then seal and protect that information under a polyester cover. The tags are weather-proof, moisture-resistant, and tamper-proof (the information cannot be altered once the tag is sealed).

Tags are rigid 0.010” plastic hanging tags with self-laminating clear polyester covers. The tag comes standard with a 0.25” metal eyelet.

Scaffold tags are also available as an adhesive-backed tag, made of 4 mil pressure-sensitive adhesive vinyl with a front self-laminating clear polyester cover. They are suitable for a wide temperature range of -50 F to 175 F. These tags are moisture-resistant and have excellent adhesion when applied to clean dry surfaces.

Stock / Custom

Available in stock and custom formats, LEM offers safety tags, warning tags, vehicle hang tags, bar-coded tags, sequentially numbered tags, biohazard tags, radiation tags and many, many more. Safety tags and warning tags are available in several styles, all of which offer excellent chemical resistance and weather ability. Stock safety tags are available in units of 25 identical tags. For more information about custom options suited to your unique application, contact us today.