What are grommets and eyelets?

Grommets and eyelets are circular metal and plastic rings inserted into mounting holes on signs and tags. The purpose is to add reinforcement and strength to the mounting holes thus avoiding any tearing of the material due to pulling and tugging on the sign or tag.

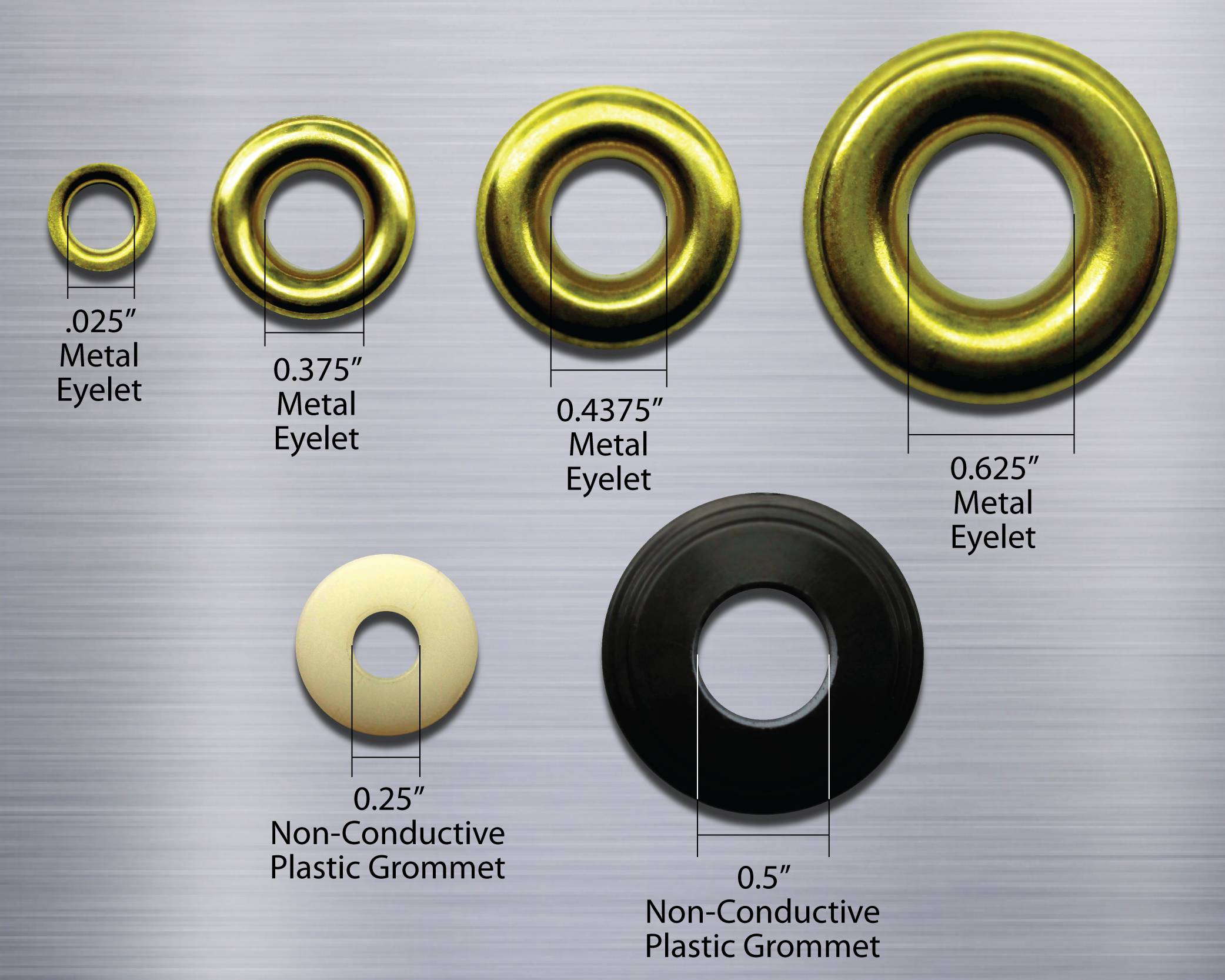

Standard eyelet diameter sizes include: 0.25”, 0.375”, 0.4375” and 0.625”. Standard grommet diameter sizes include: 0.25” (plastic) and 0.5” (plastic). These sizes are selected bas3ed on the material thicknesses. LEM can guide you for the correct eyelet or grommet when designing custom tags and signs.

How is an eyelet different from a grommet?

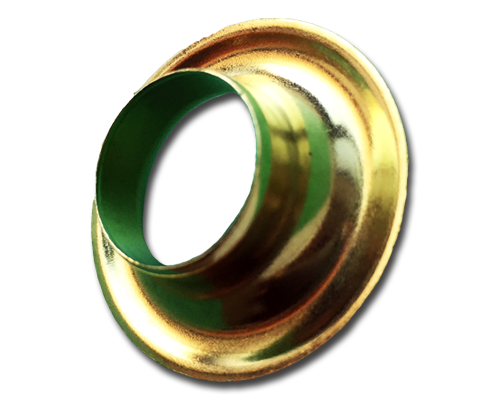

The difference between the two is that eyelets are made from one piece of metal and grommets are made from two. Eyelets are constructed with a tubular barrel section topped with a flange. When the barrel is inserted through the hole it is compressed by an eyeletting machine that crimps the barrel on the opposite side of the material from the flanged side, securing the eyelet in place.

What is a grommet?

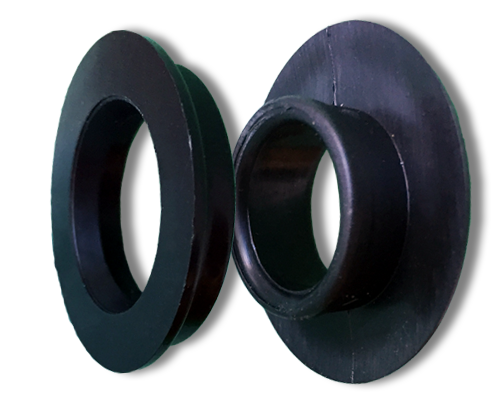

Grommets are made from two pieces of metal or plastic. One piece is slightly larger than the other. The smaller piece is compressed into the larger on the opposite side of the material and creates a reinforcement on the back side of the material. Grommets are typically used for materials that are thicker and more heavy-duty whereas eyelets are used on lighter weight materials for signs and tags that do not require an ultra-extreme pull-strength or for any custom requirements.

Both styles add superior pull-strength to all of LEM’s standard and custom Accident Prevention Tags, Lockout Tags and safety signs to make them virtually impossible to detach from their mounting positions.

Are there grommets that are non-conductive of electricity?

Plastic grommets are non-conductive for use in high voltage applications such as around electrical transformers or in power generation plants where employees are in close proximity to dangerously high amounts of electrical energy. Such situations demand a custom safety tag with a plastic grommet.