Lockout Tagout Tags

Lockout Tagout Tags are a critical warning device to alert employees about machinery that is “locked out” of operation for repair or maintenance. These tags are a component of the Lockout Tagout (LOTO) procedure to protect workers from dangerous releases of power or sudden re-energizing of machinery during routine maintenance or repair operations. Lockout tags have a clear, bold graphic appearance with standard industry legends such as, “Caution – Do Not Operate”, “Danger – Do Not Operate” and, “Danger – Equipment Locked Out. My life is on the Line” to clearly convey the critical safety information. LEM’s lockout tags conform to both ANSI (Z535) and OSHA (29 CFR 1910) standards. Lockout Tags are available in several types of material construction.

Lockout/Tagout and Hold Tags from LEM Products, Inc.

LEM Products, Inc. has lockout/tagout and hold tags that meet the rigorous requirements needed to ensure the safety of all workers in your facility. Contact us today to learn more and to ensure that you have the safety identification tags needed for your application.

How do lockout tags from LEM Products, Inc. meet code compliance for OSHA CFR 1910.147 and ANSI Z535?

Read More1910.147(a)(1)(i)

This standard covers the servicing and maintenance of machines and equipment in which the unexpected energization or start up of the machines or equipment, or release of stored energy, could harm employees. This standard establishes minimum performance requirements for the control of such hazardous energy.

Durable.

1910.147(c)(5)(ii)(A)(1)

Lockout and tagout devices shall be capable of withstanding the environment to which they are exposed for the maximum period of time that exposure is expected.

1910.147(c)(5)(ii)(A)(2)

Tagout devices shall be constructed and printed so that exposure to weather conditions or wet and damp locations will not cause the tag to deteriorate or the message on the tag to become illegible.

Lockout Tags from LEM Products, Inc. are:

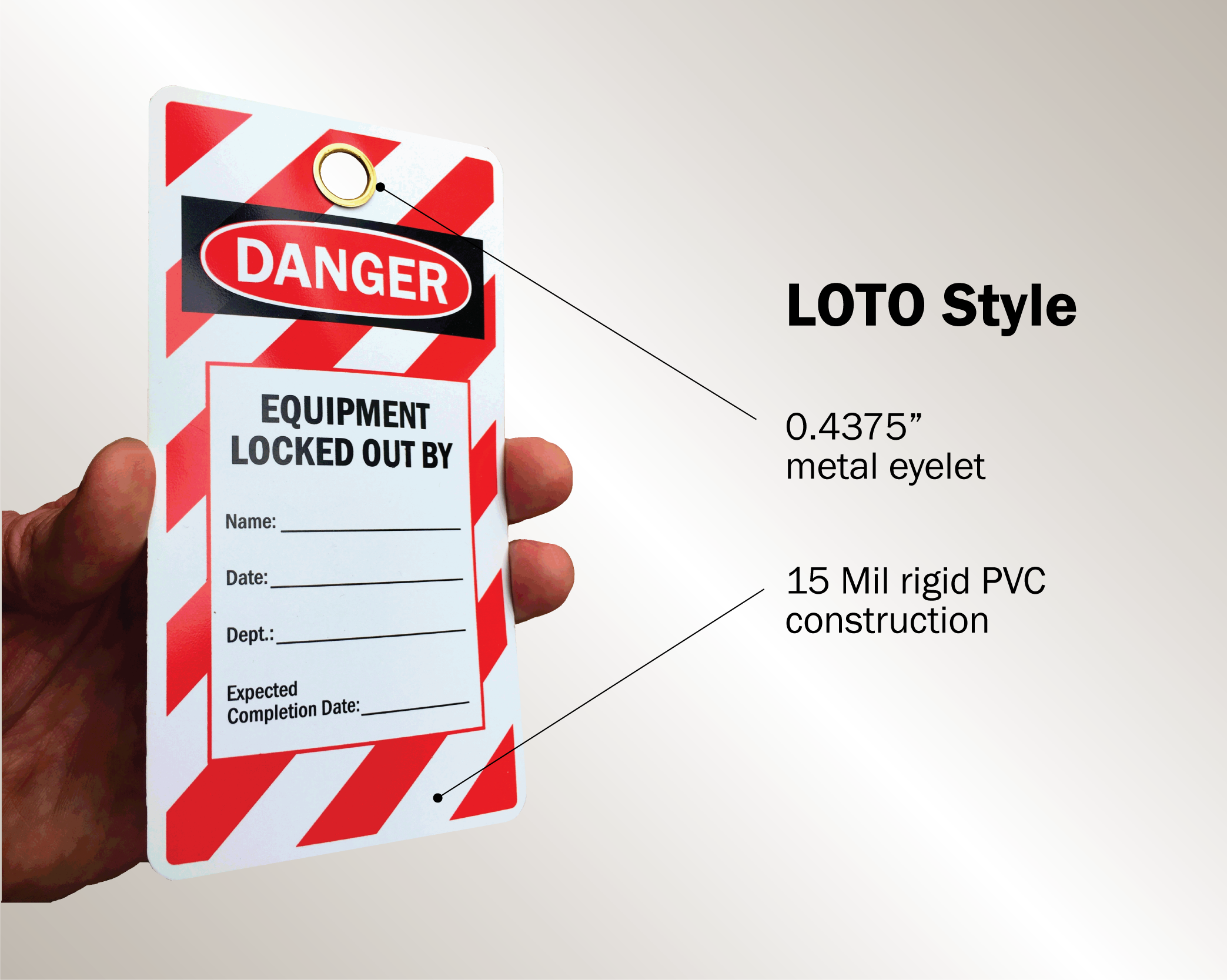

• Printed on 15 mil rigid PVC

• Moisture resistant

• UV resistant

• Resistant to common corrosive chemicals including inorganic acids, alkalis and salts

• Service temperature range of -40°F to 180°F

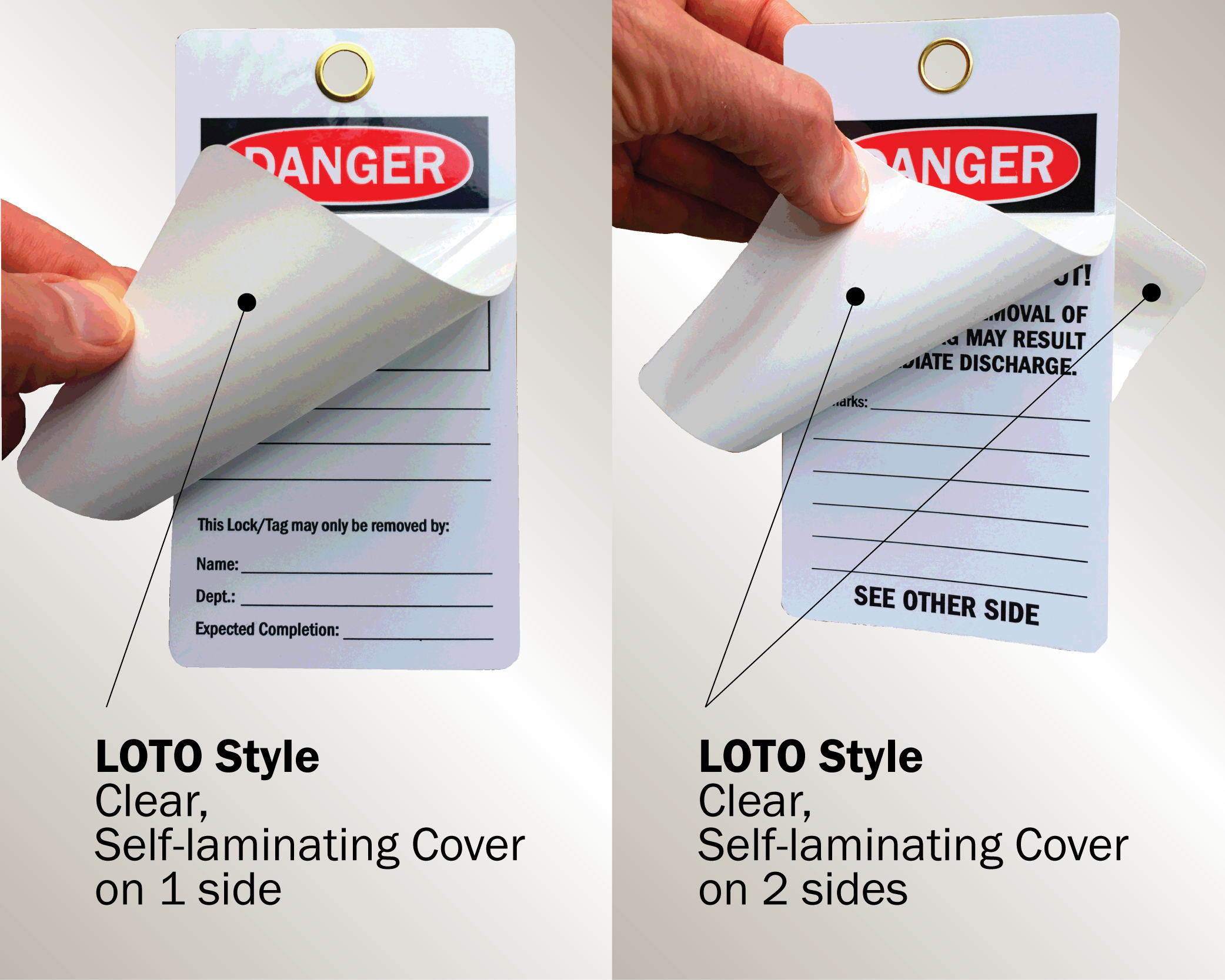

• Optional clear polyester overlaminate protects written and printed information from UV light and moisture.

1910.147(c)(5)(ii)(A)(3)

Tags shall not deteriorate when used in corrosive environments such as areas where acid and alkali chemicals are handled and stored.

Lockout tags from LEM Products, Inc. are printed on 15mil PVC which is resistant to common corrosive chemicals including inorganic acids, alkalis and salts.

1910.147(c)(5)(ii)(B)

Standardized. Lockout and tagout devices shall be standardized within the facility in at least one of the following criteria: Color; shape; or size; and additionally, in the case of tagout devices, print and format shall be standardized.

All lockout tags from LEM Products, Inc. are formatted in compliance with ANSI Z535 for color and design.

1910.147(c)(5)(ii)(C)

Substantial –

1910.147(c)(5)(ii)(C)(2)

Tagout devices. Tagout devices, including their means of attachment, shall be substantial enough to prevent inadvertent or accidental removal. Tagout device attachment means shall be of a non-reusable type, attachable by hand, self-locking, and non-releasable with a minimum unlocking strength of no less than 50 pounds and having the general design and basic characteristics of being at least equivalent to a one-piece, all environment-tolerant nylon cable tie.

LEM Products, Inc.’s lockout tags are constructed of 15 mil PVC with a metal eyelet and supplied with 8” self-locking nylon ties to withstand 50 lbs. of pull force.

1910.147(c)(5)(ii)(D)

Identifiable. Lockout devices and tagout devices shall indicate the identity of the employee applying the device(s).

All LEM Products, Inc. lockout tags include a signature line. Our tags can be written upon with pen, pencil and permanent marker. Tags have the option for a self-laminating clear polyester cover.

1910.147(c)(5)(iii)

Tagout devices shall warn against hazardous conditions if the machine or equipment is energized and shall include a legend such as the following: Do Not Start. Do Not Open. Do Not Close. Do Not Energize. Do Not Operate.

Common Legends on LEM Products, Inc. lockout tags include: Do Not Operate, Do No Start, Do Not Enter, Do Not Close, Do Not Use, Equipment Locked Out. Customized legends can be quoted to meet the customers specific requirements.

Features of Lockout Tagout Tags

LEM’s LLWT style Lockout Tag is an excellent option for a range of applications where a lockout-tagout tag is necessary for safety. Features of the LLWT tags include:

- Constructed from rigid 15 Mil PVC

- Withstands up to 50 lbs. of pull force

- Accepts pen, pencil and permanent marker

- Suitable for indoor and temporary outdoor use

Requirements for Lockout/Tagout Tags

Lockout/tagout (LOTO) requirements for tags are clearly defined by both ANSI and OSHA. LEM has been manufacturing these tags for decades, and all of our products meet or exceed these standards. According to OSHA, lockout tags must:

- Be durable enough to withstand workplace conditions, even when used near corrosive components or in wet environments.

- Meet standardized color, shape, and size requirements, be clearly legible, and offer clear instructions to employees.

- Be substantial enough to reduce the chances that the tag would be accidentally removed.

- Be labeled to identify the specific employee who is authorized to both apply and remove the tag.

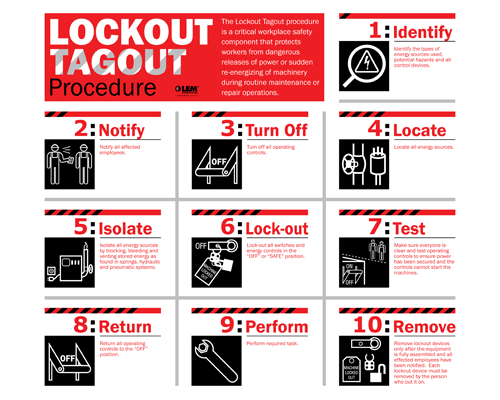

What is the Lock Out Tag Out Procedure?

One of the most frequently violated OSHA standards is the control of hazardous energy or lockout tagout (1910.147).

A Lock Out Tag Out program is a critical safety component across industries for the safety of employees during routine machine maintenance and repairs. Energy needs to be isolated to prevent the accidental start-up of the machine while employees are maintaining or repairing the machine.

The procedure should be tailored to individual machines which can seem difficult to put into practice. LEM Products, Inc.’s step-by-step infographic can be your starting point.

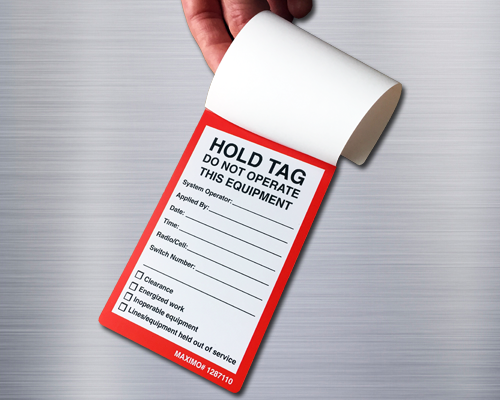

Hold Tags

Hold tags display critical directions to control processes and activities and avoid accidents, similarly to lock out-tag out tags. The bold header word, “HOLD” is supplemented with detailed pre-printed text and areas for operators and technicians to write in specific information, times, dates, and names. This can all be sealed with a protective, clear, self-laminating cover to make the information permanent.

Features of Hold Tags

Hold tags are made of rigid vinyl with 0.25” diameter brass grommets. These tags are made to withstand moisture, dirt and grease and can be written on with pencil, ballpoint pen, or permanent marker. LEM’s Hold tags meet OSHA requirements for accident prevention and are up-to-date with the most current ANSI Z535.5 recommendations for color and design. Stock tag size is 3-1/4″ x 6″. They are packaged in sets of 25 identical tags and include 25 heavy duty nylon ties.

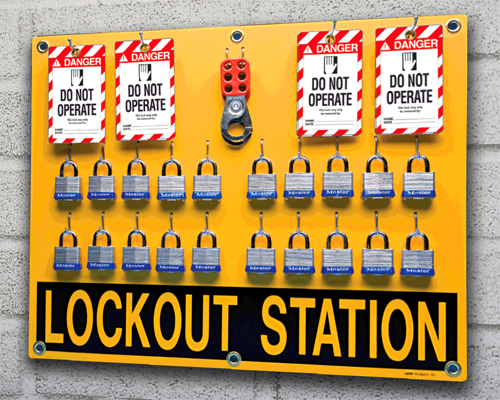

Lock Out Tag Out Stations

Lockout stations from LEM are designed to be wall mounted at a central location for necessary safety lockout/tagout components to located fast and easy for all employees. These stations and components are sold with LEM lockout tags and Masterlock® padlock locks and hasps. Custom Lock Options are:

• Keyed Alike: One key fits all locks

• Individual & Master Keyed: Each lock comes with a different key, however, a master key will open all locks.

• Standard individual locks come with 2 keys.

The 20 Position Station consists of a 24” x 19” yellow plastic board with 6 metal eyelets for mounting. There are 20 blue bumper padlocks, 50 “Do Not Operate” Tags and 6 one inch safety lock-out hasps.

The 10 Position Station consists of a 19” x 12” yellow plastic board with four metal eyelets for mounting. There are 10 blue bumper padlocks, 25 “Do Not Operate” tags and 3 one inch safety lock-out hasps.

The Individual Station consists of a 9” x 12” yellow plastic board with four metal eyelets for mounting. There are 4 blue bumper padlocks, 25 “Do Not Operate” tags and 6 one inch safety lock-out hasps. This station is used to equip each machine in your facility with an individual lock-out station.