Accident Prevention Signage for Industrial Facilities & Worksites

Original Equipment Manufacturers (OEM’s) utilize a tremendous amount of high-powered machinery. If not handled, monitored and maintained regularly, it can pose a dangerous and potentially fatal threat to work crews and maintenance personnel. An integral part of routine operation and maintenance is the use of safety identification to warn and instruct of proper procedures and potential hazards. It must also comply with local and federal safety standards.

Products & Features:

OSHA / ANSI Compliant Design

Lockout Tagout

Safety Signage

PPE Signage

Floor Markers

Hazard Tape

Barricade Tape

Outdoor Durability

UV Resistance

Moisture Resistance

Corrosion Resistance

Lockout Tag

Industrial machinery and equipment require general maintenance and repairs. The safe process for these activities requires a lockout of power and operation by means of a lock out tag out system. A lockout tagout procedure is the safeguard to maintenance personnel by preventing sudden re-energizing of the machinery and dangerous releases of power.

Accident Prevention Tags

Avoid accidents with on-the-spot Danger, Caution and Warning tags, made of rigid vinyl with brass grommets. Tags withstand moisture, dirt and grease and can be written on with pencil, ballpoint pen, or permanent marker. These tags meet OSHA requirements for accident prevention and are up to date with the most current ANSI Z535.5 recommendations for color and design.

- Danger tags: Red background with White ANSI header text

- Warning tags: Orange background with Black ANSI header text

- Caution tags: Yellow background with Black ANSI header text

A variety of pre-printed legends are displayed on the front in black on a white field along with signature and date lines at the bottom. There are optional standard texts for the reverse side of the tag that display instructional information and areas for hand written comments.

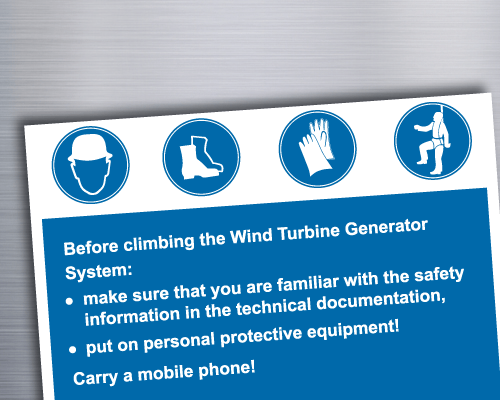

OSHA requires that employers provide a safe workplace for their employees. One part of a safe workplace is that employees utilize proper Personal Protective Equipment, or PPE, to avoid injury from certain types of hazards and situations as outlined in OSHA requirements for PPE from the Code of Federal Regulations (CFR) at 29 CFR 1910.132 (General requirements). Examples of PPE range from gloves to hard hats, eye protection, hearing protection, respirators and more.

OSHA / ANSI & ISO compliant signs with clear and succinct text and symbols help to mark and remind employees of the PPE requirements for any given hazardous situation. LEM Products, Inc. creates these in a variety of durable materials for indoor and outdoor applications.

How can I mark warehouse aisles for forklift traffic?

High-use traffic areas in warehouses where forklifts or other moving equipment travel frequently should be marked clearly to avoid accidents as per OSHA rule 1910.176(a): Permanent aisles and passageways shall be appropriately marked.

Walk-on floor markers offer a range of legends to mark for traffic control and safety. A rugged aluminum oxide grit surface is bonded to the marker making it slip-resistant and impervious to water, grease, oil, detergents and solvents.

- High contrast Black legend on Yellow background

- Denotes safety, regulatory and directional information

- Indoor and outdoor applications

- Slip-resistant

- Two sizes: 17” diameter round markers and 6” x 24’ rectangular markers.

LEM aisle and hazard marking tapes offer an OSHA compliant solution for marking dangerous areas in plants and warehouses. Available in black and yellow, black and white and additional color combinations. Hazard tape is installed rapidly and easily. It sticks to clean, dry and smooth surfaces and withstands tough indoor conditions.

OSHA Compliance with Aisle Markings (Part 1910.22(b)):

- The lines used to delineate the aisles may be any color so long as they clearly define the area considered as aisle space.

- The lines may be composed of dots, square, strip or continuous, but they too must define the aisle area.

- The recommended width of aisle markings varies from 2 inches to 6 inches; therefore, any width 2 inches or more is considered acceptable.

Suitable Applications include:

- Machinery

- Stairs

- Low beams

- Loading docks

- Doorways

- Aisles

- Guard rails

- Columns