Safety Warning Signs

LEM makes a complete line of safety signs, warning signs and caution signs for indoor and outdoor industrial, construction, warehouse and commercial work related applications. Our signs are made of embedded fiberglass, aluminum, plastic, pressure sensitive vinyl, reflective, fluorescent. Safety signs are available in hundreds of standard legends that will provide proper compliance such as Emergency and First Aid signs, Fire Safety signs, No Smoking signs, Construction signs to denote Hard Hat Areas, Machine Safety signs for regulations and proper machine operations such as danger do not operate signs, Hazardous Materials signs, Do Not Climb signs for transmission towers, Danger, Caution and Notice signs and many more to properly mark the work environment. Many stock legends are available. LEM also manufactures custom safety signs.

OSHA and ANSI Compliant

OSHA and ANSI require that work safety signs indicate and define specific hazards that, without identification, may lead to injury or death. Select your sign with the header that indicates the degree of hazard in your application.

Safety Signage for all Situations

Machine Safety Signs

Polycarbonate safety OSHA and ANSI regulatory signs

Stock and Custom Options

What is the difference between Caution, Warning and Danger?

DANGER safety signs are used to indicate that there is an immediate hazard with a high probability of death or severe injury.

WARNING safety signs indicate that there is a potentially hazardous situation, which, if not avoided, could result in serious injury or death.

CAUTION safety signs are used to alert people of a potential hazard. The hazard may result in minor or moderate injury, but not death.

Additional Safety Sign Headers

NOTICE safety signs indicate the need to provide general information to avoid confusion.

SAFETY, THINK, and EMERGENCY headings are used with information about health, housekeeping, first aid, medical equipment, and general safety.

What are OSHA and ANSI safety colors?

In addition to standardized wording, colors are assigned specific meanings in order to increase clarity of safety signs and labels. The following are the ANSI safety colors and where they should be used:

- Red: “Danger” signs, fire safety equipment, flammable liquids, emergency stop switches

- Orange: “Warning” signs, electrical hazards, work zones, exposed or moving machine parts

- Yellow: “Caution” signs, PPE instructions, common hazards, exposed edges, physical hazards

- Green: Safety signs (such as those pointing out medical equipment, first aid, emergency eyewash), general safety reminders

- Blue: “Notice” signs, maintenance, best practices

What kinds of materials are safety signs available in?

We offer safety signs in the following materials:

- Non-reflective baked aluminum

- Pressure Sensitive Vinyl

- Polycarbonate

- Reflective

Find out more about each of these materials below, and reach out to us to choose the material best suited for your specific application.

Aluminum

Aluminum – Durable, non-rusting, aluminum can be printed with enamel inks for the harshest environmental conditions. Typical thickness: .020″ – .063″

Applications

- ANSI/OSHA safety Signage

- non-critical traffic and wayfinding signs

- pole markings

- substations

- surveillance and security

- fence and gate signs

- NFPA regulatory signs

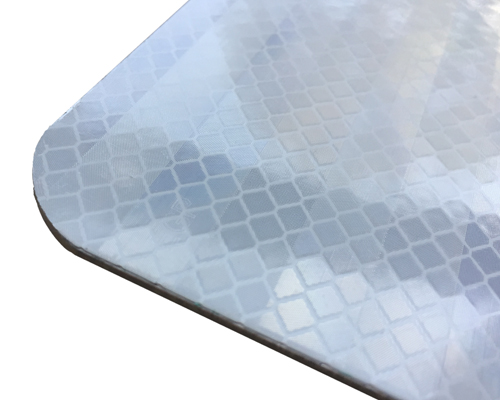

Solar Grade Polycarbonate

Solar Grade polycarbonate – Subsurface printed material for abrasion resistance, vandal-proof durability, superior UV stability and, high impact resistance. Typical thickness: .040” – .125”

Applications

- substation name signs

- high voltage signs

- fence and gate signs

- trespassing signs

- transmission tower signs

Pressure Sensitive Vinyl

Pressure Sensitive Vinyl – This permanent acrylic adhesive is suitable for all-purpose application to most any surface. It offers flexibility and durability for indoor/outdoor use. Typical thickness: .004”; UV-inhibiting laminates can be added for extended outdoor durability.

Applications

- high voltage signs

- OSHA/ANSI Safety Signs

- security and surveillance signs

- post signs

Frequently Asked Questions About Safety Signs

Can safety signs be customized?

Yes, as long as they follow OSHA’s guidelines for compliant presentation of information.

What colors fade more quickly than others?

Typically, red signs will fade faster than other colors. This is because they absorb more UV light than colors like blue and green, causing them to lose their vibrancy sooner. We minimize these effects by using UV-resistant inks in all of our signage.

What safety sign material lasts the longest?

All of the signs that we produce are made to be durable and last for many years. We can help you select which material will have the greatest longevity for your specific application.