Heavy Duty Labels for Harsh Environments

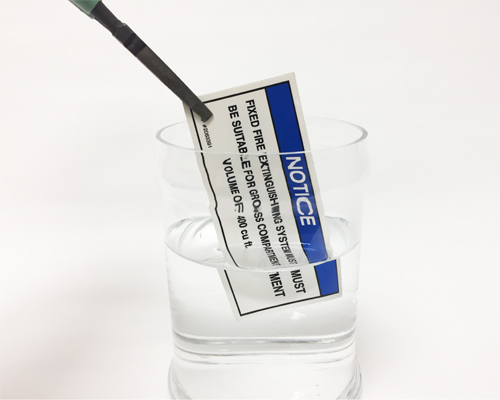

Over time, harsh environments can cause even highly durable outdoor labels to wear and fade. Prolonged exposure to heat causes materials to age more rapidly, while cold and frost heaves cause materials to contract and expand due to ground moisture. Moisture, temperature fluctuations and other outdoor factors can cause heavy duty equipment labels to lose their adhesion or become harder to read. Proper labeling of heavy duty outdoor equipment helps you and your team stay safe on the job and conform to EHS safety regulations. LEM Products, Inc., manufactures its stickers, labels, and other products using the most durable outdoor materials that can withstand extreme temperature ranges from -50°F to 250°F. Our collaborative relationships with 3M, Avery, and Flexcon guarantee the right adhesive for even the most challenging heavy duty sticker applications. Special formulations include those for adherence to corrugated, oily, slick, porous, painted, and many other surface materials and textures. Superior over-laminations protect the graphics of our permanent labels from UV radiation and moisture.

Extreme temperature ranges

Superior UV fade resistance

Non-combustible, high heat applications

Moisture, solvent and acid resistance

Abrasion resistance

Tamper Proof

Low-Temperature Application Engineer Grade Reflective Numbers

Key Features:

- Pressure sensitive adhesive.

The material is vandal-resistant and shreds when tampered with. - All markers have optical lens elements enclosed with a transparent resin that has a smooth outer surface.

- The sheetings are intended to have a similar appearance when viewed in the daylight or by retroreflective light at night.

Applicable Codes

Meets ASTM D4956 Type 1, Class 4.

Applications

This product is made specifically for low temperature applications. Labels can be applied at 10°F as opposed to standard reflective materials that have a 65°F application requirement.

Material

Engineer Grade Reflective Sheeting on White Polyethylene Coated Paper Stay-Flat Liner.

Durability

Minimum outdoor

lifespan of 10 years.

Sub-Surface Printed Solar Grade Lexan

Key Features:

- Solar grade polycarbonate.

- Sub surface printed for graphic protection.

- Back laminated to encapsulate sub-surface printing.

- Highly fade resistant.

- High impact and temperature resistance with good optical clarity.

- Rounded corners.

- 0.125” dia. mounting holes in each corner.

- 0.080” – 0.125” thickness

Durability

25 years

Polyvinylidene Fluoride (PVDF)

Polyvinylidene fluoride (PVDF) is a highly non-reactive thermoplastic fluoropolymer produced by the polymerization of vinylidene difluoride.

PVDF is a specialty plastic sheeting that LEM Products, Inc. uses to laminate products requiring protection and durability against harsh environmental conditions.

Key Features:

- Resistance to solvents and acids

- Superior UV resistance

- Moisture and grease resistant

Engravable Plastic

Key Features:

- Material Properties: UV stable, Indoor/outdoor application, With or without adhesive, Dielectric, High heat resistance, Flame retardant, Non-conductive, High contrast, Multi types: phenolic, acrylic, HDPE, “lamacoid”, “bakelite”

- Converting Methods: Rotary engraving, Laser engraving

- Applications: Nameplates, Relay & switch plates, Phenolic tags, Door signs, Control panel plates, Legend plates, Equipment tags, Valve tags

The Most Durable Permanent Safety Labels For Outdoor Equipment in Harsh Environments

When you’re labeling heavy duty equipment for outdoor use, durable and legible stickers are absolutely key. Longevity in harsh environments is important for equipment labels as well, which is why LEM Products, Inc., makes all of our labels and stickers using only the most durable adhesives and over-lamination. Temperature changes, UV radiation, and other harsh environmental factors can take their toll on outside labels and stickers, and permanent labels must be made with these factors in mind. We manufacture a wide array of permanent outdoor safety labels and stickers for different equipment, electrical identification, and a range of other purposes.

Contact us today to learn more about our permanent labels for harsh environments.