Quality Control Labels

Unyielding in quality and precision, LEM Products stands as a beacon of reliability in the arena of calibration and inspection labels and quality control labels. We are the embodiment of accuracy, guaranteeing that your equipment attains optimal performance and adheres to the highest safety standards.

Quality control (QC) or calibration and inspection labels are made for recording critical information and measurements regarding calibration, maintenance, inventory, and quality control. These QC stickers can also denote the operating and inspection status of industrial equipment, devices, parts, and products. The labels from LEM Products, Inc. are ideal for original equipment manufacturers (OEM), maintenance, repair, and operations (MRO) products, and water utility safety identification products.

Our calibration and inspection labels are designed to withstand harsh environments and extreme conditions, ensuring that they remain legible and intact throughout the lifespan of your equipment. Our pre-printed labels have a variety of legends, including:

- Accepted

- Calibration

- Tested

- Inspected

- Shelf Life

- Rejected

- Rework

- Serviced

- And More!

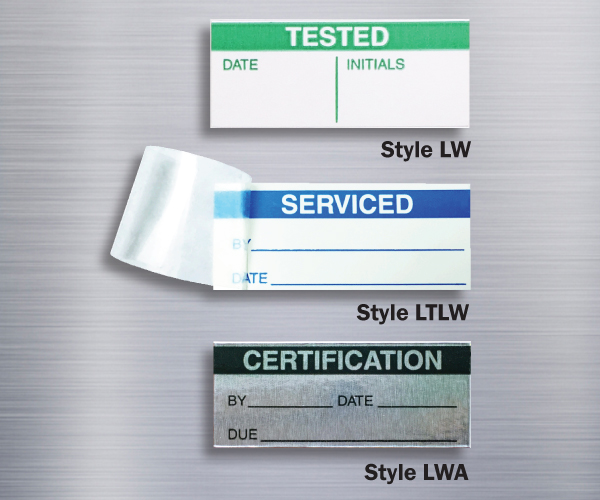

There are also spaces for handwritten information, such as CHECKED BY, DATE, DUE, REASON, INITIALS, etc. We proudly offer calibration and inspection labels in different sizes, shapes, and options. It’s important to note that these labels are for indoor use only.

Contact us today to learn more and acquire proper labeling for your industry needs.

What Are Calibration and Inspection Labels?

Calibration and inspection — also referred to as quality control labels — are essential tools for maintaining the accuracy, safety, and compliance of your equipment. These labels serve as visual indicators, providing crucial information about the status of machinery, tools, or devices. They typically include details about when the equipment was last inspected or calibrated, who performed the service, and when the next service is due. By using these labels, businesses can ensure their equipment performs at its peak efficiency, minimize downtime, and stay compliant with industry regulations.

Calibration and Inspection Labels for Your Industry

Calibration and inspection labels span across a multitude of industries, each with its unique requirements and standards. This includes:

- Manufacturing

- Healthcare

- Aviation

- Oil and Gas

- Food and Beverage

- Distribution

- Utility Companies

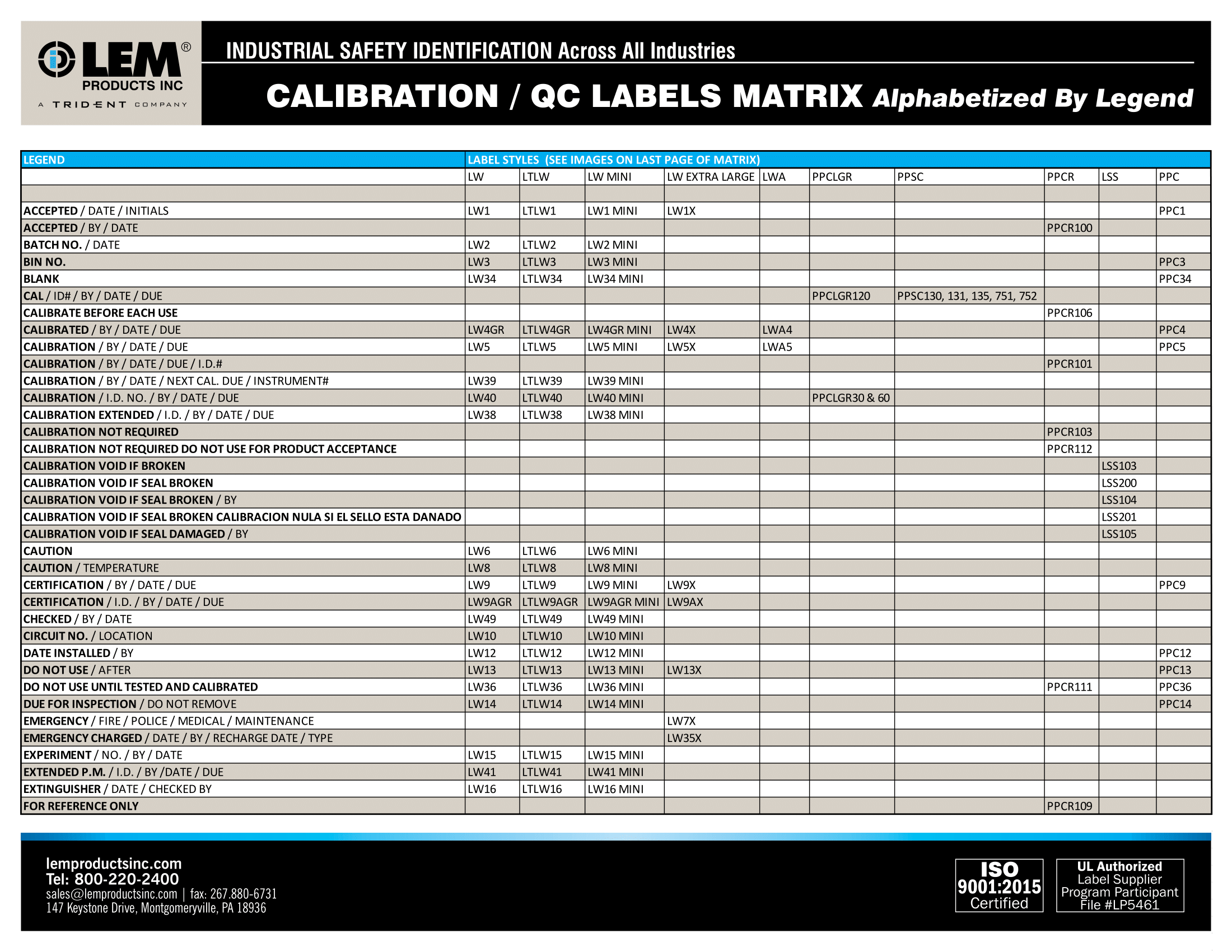

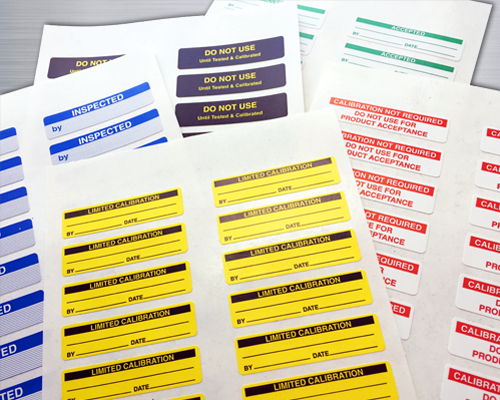

Write-On Removable Quality Control Labels — PPCR Style

Our PPCR-style write-on control labels are made of writeable vinyl material with a removable adhesive. These labels accept marks from pens, pencils, felt-tip writing instruments, typewriters, and rubber stamps. They resist grease, oil, dirt, and moisture. PPCR labels measure 0.5” x 2” with 16 markers per card and are available in packages of 10 cards.

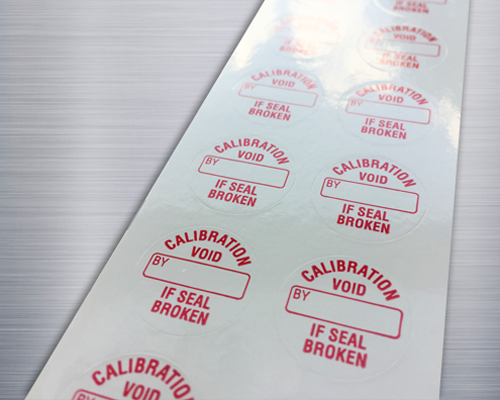

Round Tamper-Proof Security Seals — LSS Style

The LSS-style security seals are made from tamper-proof frangible vinyl and are designed to tear upon any attempt at removal. They are available in two sizes: 0.75” diameter and 2” x 0.5”. You will be supplied 20 labels per card. We sell them in packages of 10 cards with 200 labels per package.

Wrap-Around Write-On Calibration Labels — PPCLGR Style

Our PPCLGR-style write-on control labels are also made of the same writeable vinyl material. The write-on area is white with green text and has a clear self-laminating tail. You can wrap the label around tubes or handles and back over the printed area to secure the label and protect the information printed on it. Labels vary in size from 1” x 3”, 1” x 6”, 1.25” x 12”, and 0.25” x 6”. They are available in packages of 10 cards.

Circular Write-On Vinyl Control Labels — PPSC Style

The PPSC-style are circular write-on vinyl control labels with permanent adhesive. These round calibration labels accept pens or pencils. Most stickers have a self-laminating clear polyester cover so that written information can be sealed and protected from grease, oil, dirt, and moisture. These quality control stickers measure 0.5” and 0.75” in diameter. When you order PPSC labels, you will be supplied with 25 labels per card. We sell these labels in packages of 7 cards.

Round Tamper-Proof Security Seals — LSS Style

Round Tamper-Proof Security Seals — LSS Style

The LSS-style security seals are made from tamper-proof frangible vinyl and are designed to tear upon any attempt at removal. They are available in two sizes: 0.75” diameter and 2” x 0.5”. You will be supplied 20 labels per card. We sell them in packages of 10 cards with 200 labels per package.

Why Are Quality Control/Calibration and Inspection Labels Needed?

Calibration and inspection labels are vital components for businesses that utilize machinery or equipment in their operations. Their primary purpose is to ensure the accuracy and efficiency of your equipment. If equipment is inaccurate or faulty, it can lead to errors or poor-quality results, negatively impacting productivity and tarnishing your business’s reputation. In addition, many industries have regulatory standards that mandate regular calibration and inspection of equipment. These labels serve as a visible record of these activities, helping your business maintain compliance and steer clear of potential legal issues or penalties.

Quality control stickers and labels can be used in a variety of ways. As discussed above, manufacturers, healthcare companies, distribution companies, and utility companies often use these labels to ensure specifications are met for products, materials, and equipment. Most commonly, QC labels are used for:

- Machine Calibration and Inspection

- Service and Maintenance Completion for Equipment

- Product Pass/Fail During Quality Inspections

- Relaying Shelf Life Information

Regular inspections, indicated by these labels, can help identify potential problems before they escalate, contributing to a safer working environment. These labels also provide plenty of cost savings by keeping track of maintenance schedules, thereby preventing unexpected equipment breakdowns and repairs.

How Do I Choose the Best QC Label for My Needs?

When you’re looking into investing in quality control stickers, you will need to consider a few factors, including:

- The label’s adhesive properties: Since control labels are frequently replaced as the process progresses or is repeated, you need stickers that feature a temporary adhesive that stays in place for as long as you need but can also be easily peeled off at the appropriate time.

- The label’s size: Make sure you choose QC stickers that are large enough to display any necessary information and catch technicians’ eyes at a glance.

- The label’s ability to withstand heat: If your labels have not been designed for use with warm equipment, the label could fade, losing all of your crucial information. You will also want to make sure the sticker’s adhesive can withstand the temperature of the equipment and will not lose its stickiness.

- The label’s security features: If it’s crucial that your quality control labels remain in place, you will want to choose tamper-proof stickers so that you know immediately if someone tried to mess with them.

read More

Get Custom Calibration and Inspection Labels

LEM Products takes pride in offering custom calibration and inspection labels designed to meet your business’s distinct requirements. Our focus is on creating solutions that are as unique as your operational needs. From labels that can endure extreme temperatures to those capable of withstanding harsh environments, our experienced team crafts each label with precision and expertise.

We also concentrate on design details such as color-coding, sequential numbering, or barcoding, all aimed at enhancing your equipment management efficiency. We deliver labels with clear, legible information, utilizing high-quality materials and advanced printing technology, even under challenging conditions.

What Information Is Typically Included on These Labels?

Calibration and inspection labels typically include important data, such as:

- The date of the last inspection or calibration.

- The due date for the next one.

- The identity of the person who performed the task.

- Any relevant equipment identification numbers or barcodes.

This information is vital in maintaining a consistent schedule and ensuring compliance with industry standards and regulations.

Are These Labels Resistant to Harsh Conditions?

As for resilience, yes, our calibration and inspection labels are designed to withstand harsh conditions. Crafted from the best materials, these labels resist elements like extreme temperatures, moisture, chemicals, and abrasion, ensuring that the vital information they convey remains legible and intact over time.

Turn to LEM Products for the Labels You Need

Calibration and inspection labels are vital components to any inspection or calibration operation, and LEM Products provides some of the finest options for any organization. Contact us today to secure the labels your industry needs. We also provide pressure sensitive labels for electrical transformers and weather resistant warning labels, delivering versatility like none other. Secure what you need today.