EHS-Compliant Work Safety Signs

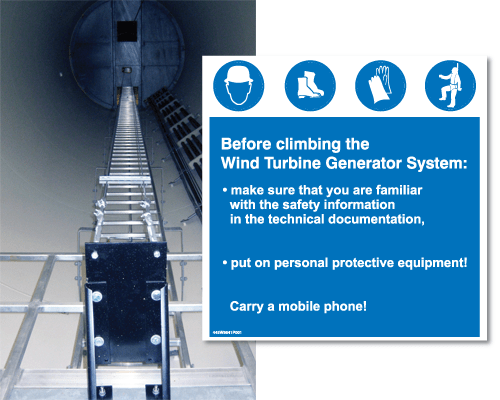

Part of maintaining an efficient and compliant Environmental Health & Safety (EHS) program involves the assessment of risks and identification of potentially hazardous situations, processes and materials in the workplace to avoid accidents and injuries. It also involves maintaining compliance with government regulations for safety to individuals, departmental procedures as well as environmental impact.

Safety Hazards

Ergonomic Hazards

Environmental Hazards

Chemical Hazards

Biological Hazards

Work Organization Hazards

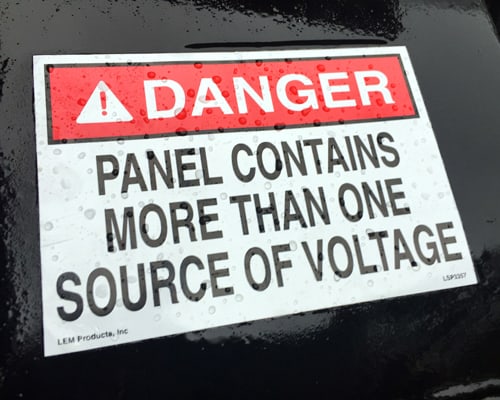

LEM’s products display the ANSI compliant headers to denote the level of hazard: Notice, Caution, Warning and Danger. LEM’s safety identification products are made from a variety of outdoor durable materials to withstand harsh industrial environments, corrosion, moisture resistance and UV resistance so that the information is clearly displayed no matter what severe conditions the environment poses.

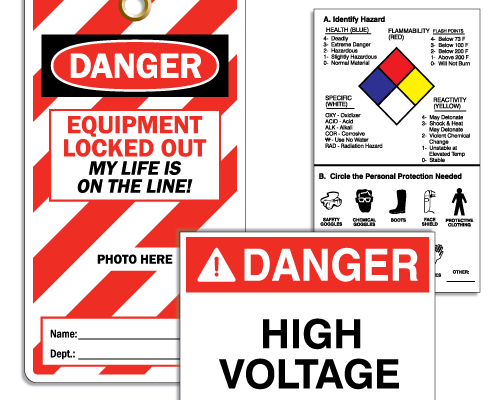

Industrial machinery and equipment require general maintenance and repairs. The safe process for these activities requires a lockout of power and operation by means of a lock out tag out system. A lockout tagout procedure is the safeguard to maintenance personnel by preventing sudden re-energizing of the machinery and dangerous releases of power.

LEM manufactures a huge variety of standard identification tags and labels and signs. OEM’s will invariably require customized legends and sizes to accurately convey safety and instructional information. Construction sites require signage to warn of hazardous conditions and dangerous areas such as hard hat areas and the use of proper Personal Protective Equipment or PPI.

An integral part of routine operation and maintenance is the use of safety identification to warn and instruct of proper procedures and potential hazards. It must also comply with local and federal safety standards. LEM is a manufacturer and supplier of compliant industrial safety labels, tags and signs to OEM’s and industrial fabricators.