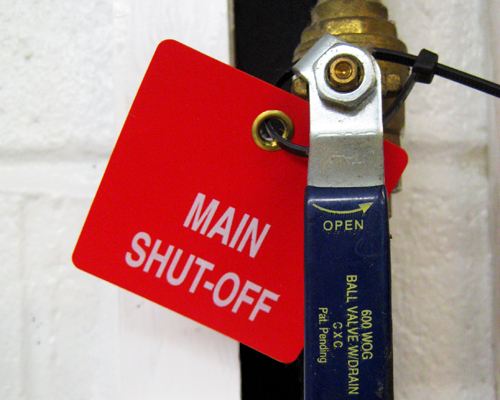

In various industrial applications, valves control the flow of contents throughout a piping system. In certain applications, the pipe’s contents may be hazardous. In others, the materials may be stored at high pressures. In either case, safety protocols are necessary to ensure employees and contractors understand how to use the pipe system properly. The best way to do this is to mark valves with valve identification tags.

Here is everything you need to know about properly tagging valves throughout your facility.

Why Valve Tags Are Necessary

Most facilities, warehouses, and factories have numerous utility pipes and valves. Without a sophisticated pipe marking system, it can easily become confusing which pipe is carrying which contents. Confusion leads to mishaps and potentially fatal injuries. Luckily, valve and pipe labeling can minimize the number of accidents associated with using pipe systems. These are some of the top benefits of using valve tags:

- Semi-Automate Asset Management: While many valves operate on some level of automation, they may require manual maintenance and repairs from time to time. Placing a tag on each valve can enable employees and contractors to use the barcodes and other identifying information to keep track of assets and their conditions.

- Prevent Misidentification: Valve and pipe markers allow facility managers to include any pertinent information on the label so there’s less risk of accidents due to confusion. Custom tags can also be color-coded to match your facility’s categorization standards.

- Communicate Potential Hazards: One of a valve tag’s greatest benefits is its ability to instantly communicate the presence of potential dangers. It can do so using colors, graphics, or information.

Pipe and Valve Marking Standards and Regulations

In the United States, the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers set regulations in place for piping systems to reduce the risk of accidents and injury. The ANSI/ASME A13.1 states that pipes and valves must be tagged with an identification label. The recommended method for doing this is creating a tag numbering system and using the following predefined colors:

- White text on red background for fire-extinguishing fluids

- Black text on orange background for corrosive fluids

- Black text on yellow background for flammable fluids

- White text on brown background for combustible fluids

- White text on green background for water

- White text on blue background for compressed air or other gasses

When placing your valve tags, remember:

- The tags should be easily accessible.

- The valve markers should be visible from different points of view.

- The tags should not be placed on the valve stems, actuators, or other components essential to the operation of the valve.

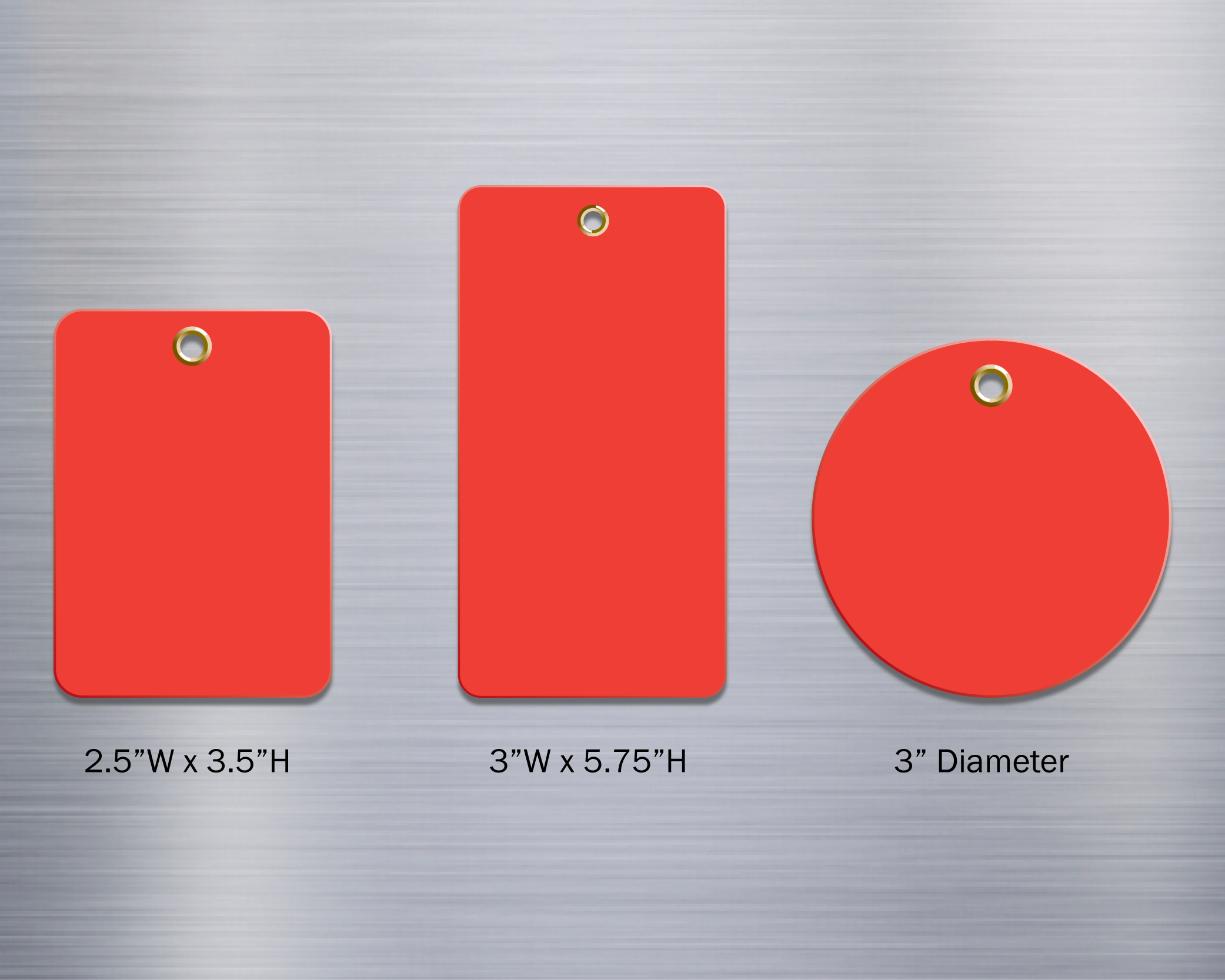

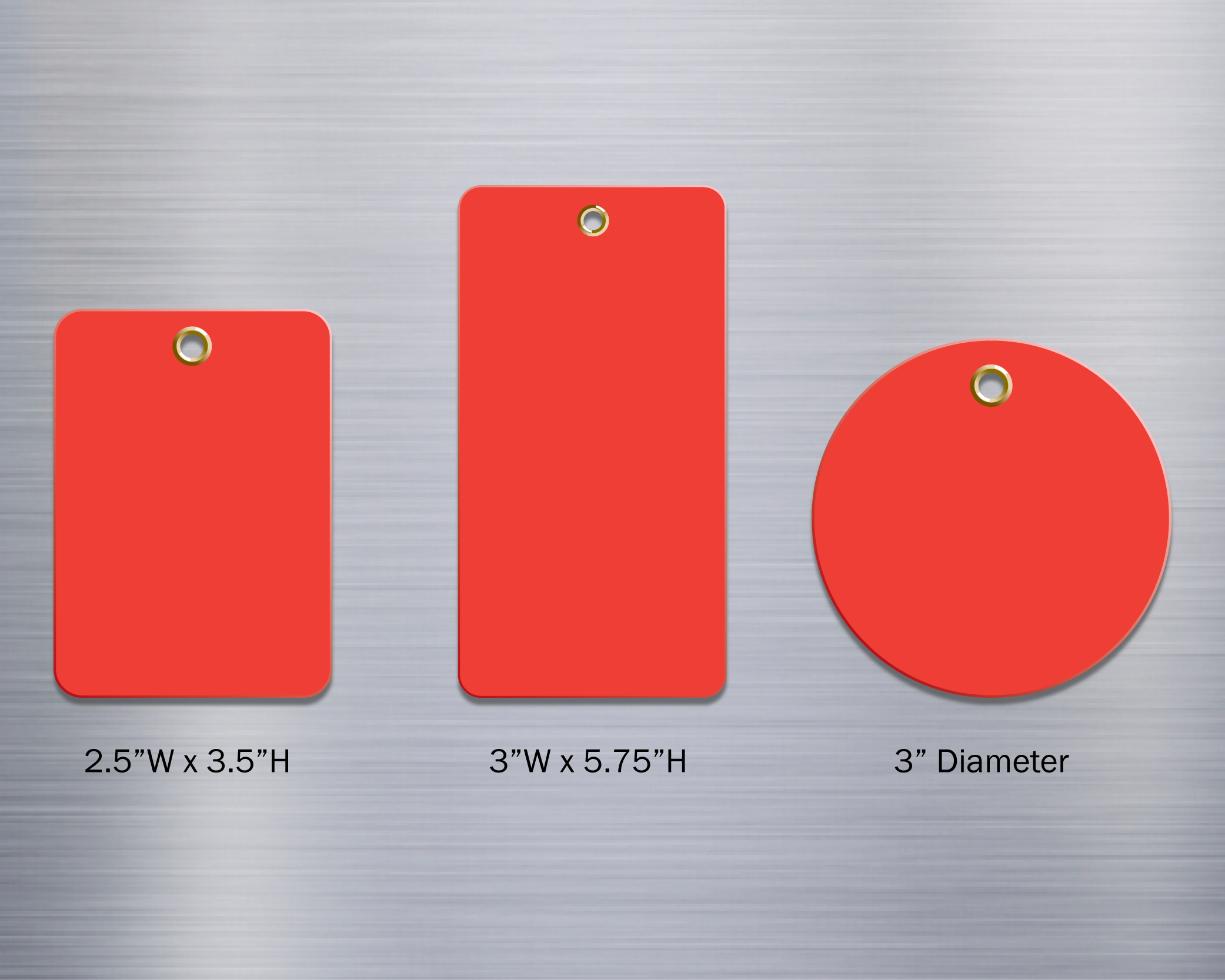

Types of Valve Tags

Your facility will likely require different valve tags based on the application for which the valve is used. Here are the different types of tags used for facilities’ pipes and valves:

- Chemical Valve Tags: You will need these tags to mark valves connected to pipes with chemical contents. These tags are essential for maintaining safety throughout your facility.

- Waste/Water Pipe Valve Tags: You will want to use these tags to mark valves associated with water and wastewater pipes. You don’t want someone to turn on the valve expecting potable water only to get wastewater.

- Gas Valve Tags: When you have pipes with hot liquids, steam, or other gasses, you will want to properly tag them so that a person does not open the valve and get severe burns or injuries.

- Lock Out, Tag Out (LOTO) Tags: When equipment is being repaired or worked on, you will need to place a LOTO tag on the valve to mark it as inoperable. These specialized tags ensure you are OSHA compliant and protect the health and safety of everyone in your facility.

- Metal Valve Tags: Metal valve markers are highly durable and can be customized to meet your needs. You can choose aluminum, stainless steel, or brass for your industrial labeling system.

- Plastic Valve Tags: Plastic valve labels are a very economical choice for custom tags. They can be printed in high volumes and made of vinyl, polyester, or polycarbonate.

Get Your Valve Tags Today

No matter the type of contents flowing through your piping system, it’s crucial to have a valve tagging system in place. Once you develop a system that works for your facility, make sure you train all your employees on the tagging procedure so that everyone can remain safe at all times.

At LEM Products, Inc., we manufacture a variety of identification and safety tags for piping systems, including valves. We can help you choose the right materials and color schemes for your tagging system. Order your tags online today, and don’t hesitate to reach out with any questions.