As an industrial business owner, you know how important it is to make sure your employees and customers are safe in the workplace. One of the ways to do this is by having a reliable equipment lockout procedure in place. Having a comprehensive lockout procedure can help to reduce safety risks and protect everyone on-site from any potential danger. However, there may be some occasions when you feel like your current lockout procedure could use an upgrade. One of the areas where you can see an immediate improvement in your operations revolves around lockout/tagout tags. Continue reading “How Can You Upgrade Your Equipment Lockout Procedure?”

Author: nbeste

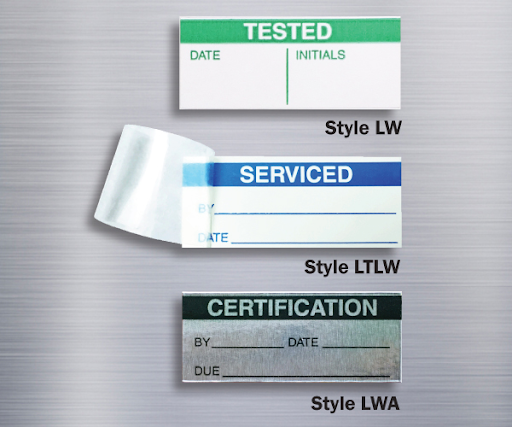

How to Stay OSHA Compliant With Quality Control Labels

In the public works sector, ensure your facility and any machinery you have remain in the best condition possible. If an issue makes a particular item non-compliant, you need to have a clear way of ensuring that everyone is aware and properly documented. While your employees may know not to use a specific piece of equipment, without the proper labeling and documentation, you are not in compliance with OSHA standards. Many organizations can become OSHA compliant with quality control labels from LEM products, and here are some of the ways we can help. Continue reading “How to Stay OSHA Compliant With Quality Control Labels”

How to Protect Water Sources With Proper Signage

Water distribution systems provide a vital service for people across the country. They work to deliver clean water to homes and businesses as efficiently as possible without any disruptions in their network. A significant component of this is protecting the primary source of their supply. From wells, deep groundwater, aquifers, springs, rivers, and more, taking the necessary precautions to protect these sources from potential contamination remains vital. Continue reading “How to Protect Water Sources With Proper Signage”

Which Safety Signs Should Your Facility Have?

No matter what business you run, safety and security should be at the top of your list of essential requirements. Ensuring people are safe while performing daily tasks in your facility is of the utmost importance, which rings especially true in high-traffic environments. With clients and products coming in and out and workers quickly moving through various sections, there are plenty of ways signs can help direct traffic and keep your facility running smoothly for years to come. Here are some of the most important safety signs your facility should have. Continue reading “Which Safety Signs Should Your Facility Have?”

Everything You Need to Know About Hydrant Rings

Having access to an adequate amount of water could spell the difference between the total destruction of a building and life or death. For this reason, it’s crucial fire hydrants be tested for flow every five years and inspected annually, according to the National Fire Protection Association (NFPA). When inspection season approaches, city professionals and licensed contractors must ensure their teams are equipped with the proper fire hydrant identification tags. Here’s what you need to know about the warnings written on hydrant rings, their colors, diameters, and materials. Continue reading “Everything You Need to Know About Hydrant Rings”

The Importance of Valve Tags in Marking Piping

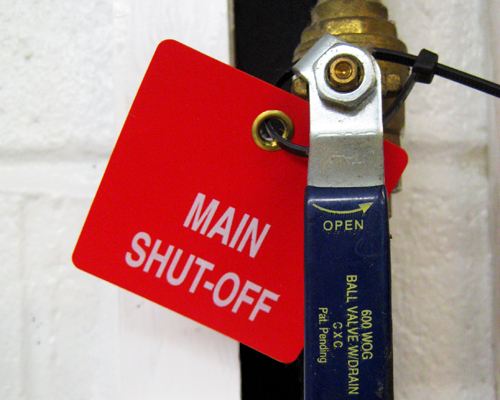

In various industrial applications, valves control the flow of contents throughout a piping system. In certain applications, the pipe’s contents may be hazardous. In others, the materials may be stored at high pressures. In either case, safety protocols are necessary to ensure employees and contractors understand how to use the pipe system properly. The best way to do this is to mark valves with valve identification tags.

Here is everything you need to know about properly tagging valves throughout your facility.

Why Valve Tags Are Necessary

Most facilities, warehouses, and factories have numerous utility pipes and valves. Without a sophisticated pipe marking system, it can easily become confusing which pipe is carrying which contents. Confusion leads to mishaps and potentially fatal injuries. Luckily, valve and pipe labeling can minimize the number of accidents associated with using pipe systems. These are some of the top benefits of using valve tags:

- Semi-Automate Asset Management: While many valves operate on some level of automation, they may require manual maintenance and repairs from time to time. Placing a tag on each valve can enable employees and contractors to use the barcodes and other identifying information to keep track of assets and their conditions.

- Prevent Misidentification: Valve and pipe markers allow facility managers to include any pertinent information on the label so there’s less risk of accidents due to confusion. Custom tags can also be color-coded to match your facility’s categorization standards.

- Communicate Potential Hazards: One of a valve tag’s greatest benefits is its ability to instantly communicate the presence of potential dangers. It can do so using colors, graphics, or information.

Pipe and Valve Marking Standards and Regulations

In the United States, the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers set regulations in place for piping systems to reduce the risk of accidents and injury. The ANSI/ASME A13.1 states that pipes and valves must be tagged with an identification label. The recommended method for doing this is creating a tag numbering system and using the following predefined colors:

- White text on red background for fire-extinguishing fluids

- Black text on orange background for corrosive fluids

- Black text on yellow background for flammable fluids

- White text on brown background for combustible fluids

- White text on green background for water

- White text on blue background for compressed air or other gasses

When placing your valve tags, remember:

- The tags should be easily accessible.

- The valve markers should be visible from different points of view.

- The tags should not be placed on the valve stems, actuators, or other components essential to the operation of the valve.

Types of Valve Tags

Your facility will likely require different valve tags based on the application for which the valve is used. Here are the different types of tags used for facilities’ pipes and valves:

- Chemical Valve Tags: You will need these tags to mark valves connected to pipes with chemical contents. These tags are essential for maintaining safety throughout your facility.

- Waste/Water Pipe Valve Tags: You will want to use these tags to mark valves associated with water and wastewater pipes. You don’t want someone to turn on the valve expecting potable water only to get wastewater.

- Gas Valve Tags: When you have pipes with hot liquids, steam, or other gasses, you will want to properly tag them so that a person does not open the valve and get severe burns or injuries.

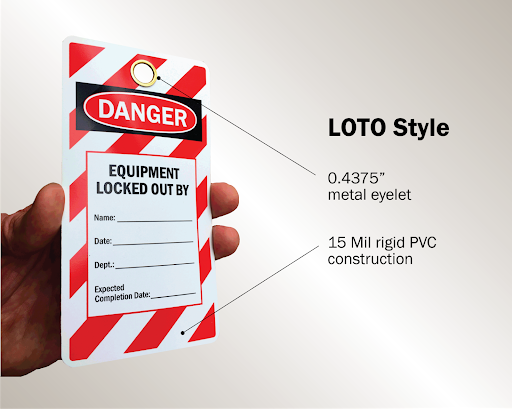

- Lock Out, Tag Out (LOTO) Tags: When equipment is being repaired or worked on, you will need to place a LOTO tag on the valve to mark it as inoperable. These specialized tags ensure you are OSHA compliant and protect the health and safety of everyone in your facility.

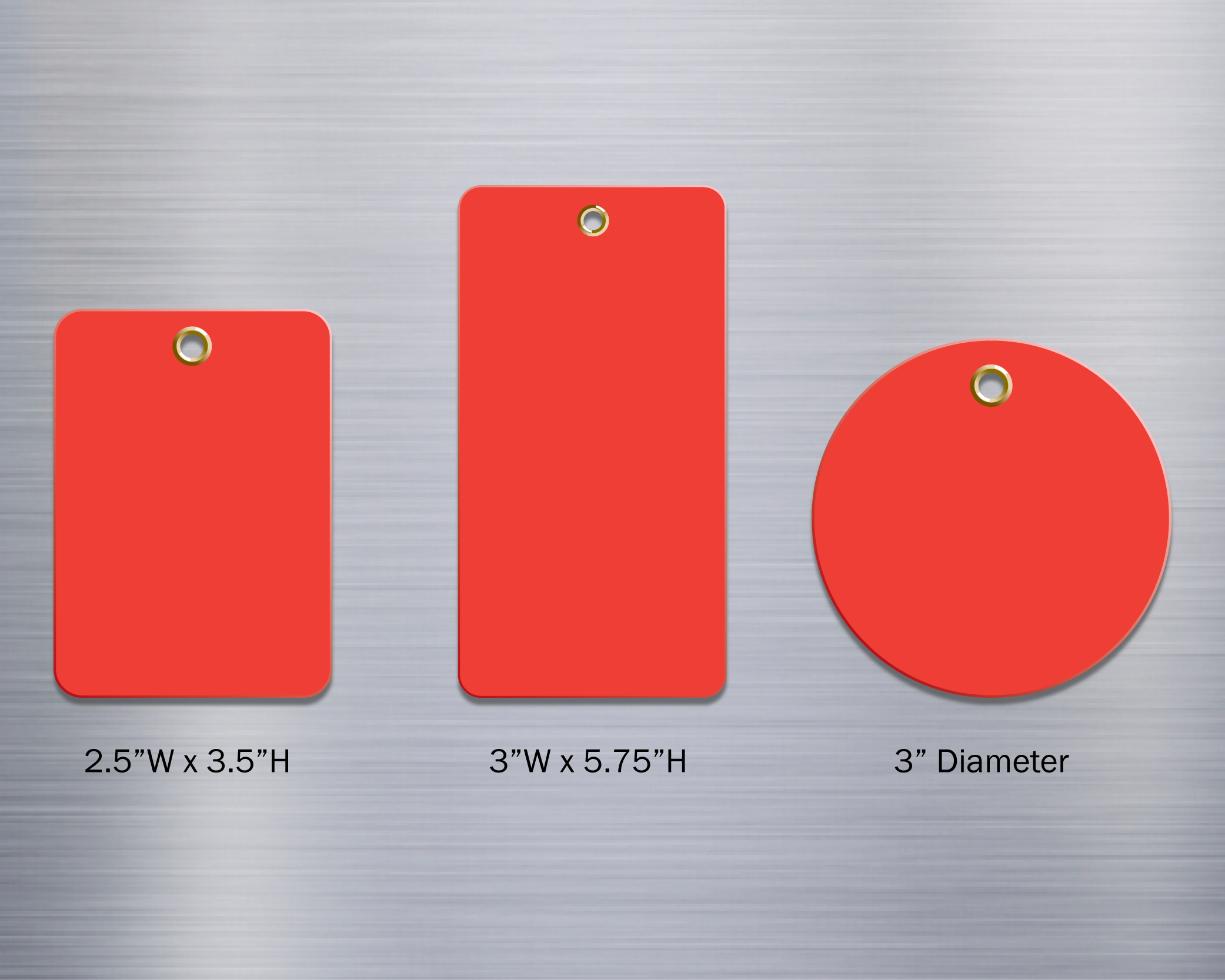

- Metal Valve Tags: Metal valve markers are highly durable and can be customized to meet your needs. You can choose aluminum, stainless steel, or brass for your industrial labeling system.

- Plastic Valve Tags: Plastic valve labels are a very economical choice for custom tags. They can be printed in high volumes and made of vinyl, polyester, or polycarbonate.

Get Your Valve Tags Today

No matter the type of contents flowing through your piping system, it’s crucial to have a valve tagging system in place. Once you develop a system that works for your facility, make sure you train all your employees on the tagging procedure so that everyone can remain safe at all times.

At LEM Products, Inc., we manufacture a variety of identification and safety tags for piping systems, including valves. We can help you choose the right materials and color schemes for your tagging system. Order your tags online today, and don’t hesitate to reach out with any questions.

5 Tips for Improving Your Lockout/Tagout Program

Lockout/tagout (LOTO) is a procedure developed to protect employees and other workers from the unexpected startup of machinery under maintenance or repair. A successful LOTO program ensures that the faulty machinery is entirely shut down, has been tested for residual energy, and will not be started again until the proper time. Lockout procedures are implemented to prevent serious and fatal injuries from hazardous energy. Improving your lockout/tagout program enhances workplace safety and compliance. Continue reading “5 Tips for Improving Your Lockout/Tagout Program”

The All-Encompassing Guide to Telecommunications Equipment Tags and Labels

There’s an incredible amount of equipment involved in telecommunications, and each piece needs its own asset or pole identification. Otherwise, vital safety warnings, ownership identification, location tracking, and service maintenance information could be missing. Telecom labels and tags will provide this valuable information and ensure telecom technicians perform their duties well.

Continue reading “The All-Encompassing Guide to Telecommunications Equipment Tags and Labels”

What Should Be Included on a GHS Label?

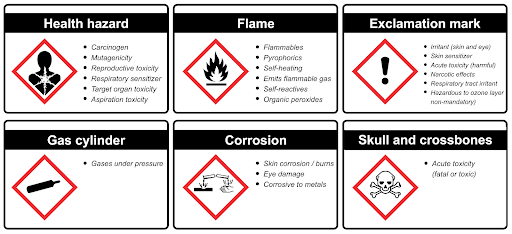

Safety is of the utmost importance when you are handling chemical products or other hazardous materials. In 2012, Globally Harmonized System of Classification and Labelling of Chemicals (GHS) labels were officially made a part of OSHA’s required hazard communication standards. This means that chemical manufacturers and other industry professionals are legally required to adhere to these labeling requirements. GHS-compliant labels don’t always look exactly the same, but six specific GHS label requirements must always be followed:

LEM Products, Inc.’s 2021 Charitable Holiday Festivities

Last year, we at LEM changed our tradition of hosting a holiday luncheon to holding a silent auction that focused on holiday gifts. Our staff bid on toys and got a head start on their holiday shopping, with all proceeds from the auction being donated to a charity. In 2021 we continued this new tradition and held our second annual Silent Auction that’s proceeds surpassed last year’s achievement.

Helping Veterans and First Responders

This year, the proceeds from our auction are being donated to the Tunnels for Towers Foundation, a charitable foundation that provides mortgage-free smart homes for catastrophically-injured veterans and first responders. The smart homes are designed and built to accommodate wheelchair access with wider doors and hallways, automated door openers, automated lighting, and much more to help these veterans and first responders reclaim day-to-day independence.

As 2021 comes to a close, we are grateful that we are able to continue to support noble causes like the Tunnels to Towers Foundation and give back to those who have sacrificed so greatly for our country.