Telecom Safety Signage for Underground Installation

Underground installation of fiber optic cables for digital infrastructure utilizes different methods depending on various factors from terrain to cost to local codes. Whichever method is chosen, safety identification is common to all.

In underground installations, fiber optic cables are housed in protective tubes or conduits. These are buried by open trenching or boring techniques. The fibers are pulled or injected through the conduits in segmented lengths.

Cable access varies depending upon the depth of the installation. Smaller cable access boxes are typically used for shallow depth cables. Deeper burials can utilize cable vaults with manhole access or they can be run through cable tunnels.

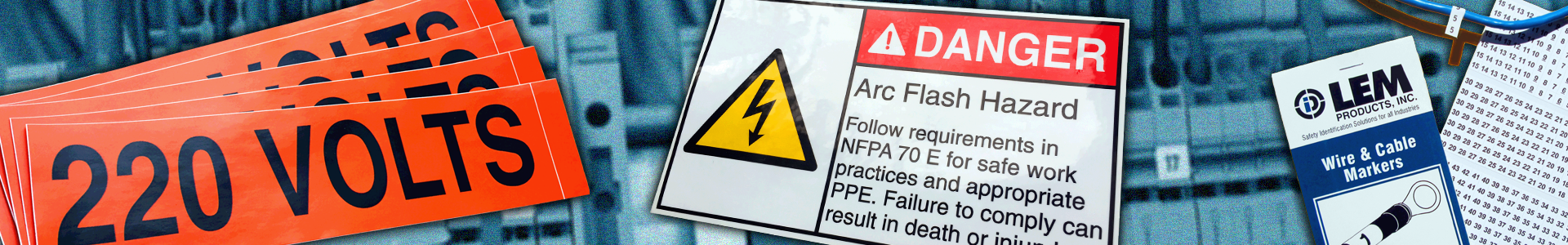

Tagging, labeling and identifying telecom cables for safety, cable type, ownership and location takes different forms and must be durable and resistant to moisture and the elements as well as being tamper-proof.

How are telecommunication cables identified to know what they are and what company owns them?

Snap Around Cable Markers are pre-curled PVC with elastic memory. They open to accept the cable and then snap around it for a secure fit. These cable markers are pre-printed with customized information such as the cable type and ownership information. They can accept cables up to 3.25” in diameter and come in various color combinations.

Fiber Optic Cable tags are pre-printed on PVC with space for entering your custom information such as fiber type and count. They are also available as blank tags. Each fiber optic tag has 6 slotted holes to allow for attachment to cable bundles with nylon ties. Self-laminating covers protect information from moisture. Tags measure 2” x 3.5”.

Underground residential transmission (URD) tags provide another format for marking underground telecom cables. These PVC tags are blank and can be written upon with pen or pencil and sealed with a self-laminating cover for protection against corrosion, moisture, and tampering. Sizes range from 1.5″ x 3.0″ to 2.5″ x 5.75″.

How to find buried telecom cables?

Buried Detectable Utility Line Tapes are printed on an aluminum core so that metal detectors can identify their location underground. This allows for locating without excavation.

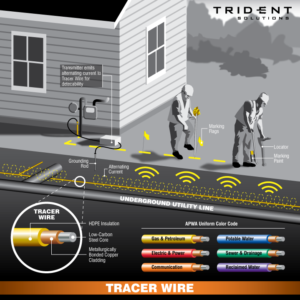

Tracer Wires are installed along utility and telecommunications lines to trace their locations conductively for detection above ground. A transmitter emits alternating current to the tracer wire for detectability by a locator above ground. Various construction types, gauges and colors are available to accommodate different utility, telecom, and construction installations.

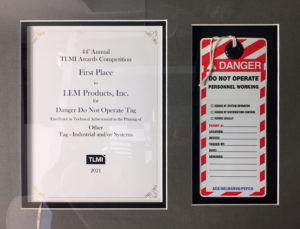

LEM Products, Inc. offers many standard safety and cable identification tags and labels for the telecommunications industry. If you need a customized legend or text on a label or tag, contact us today.